1. BellaTek® Encode® Gingiva former on an implant in Region 36

The patented BellaTek® Encode® impression system of Zimmer Biomet offers a gingiva former, serving as scanbody at the same time. Thus, frequent Abutment changes are prevented and working steps in the practice are reduced. This digital impression is suitable for the transmission of the implant position, orientation and height.

After data transmission to a Zfx partner laboratory, the abutment and crown are designed through the use of a special software feature (Zfx™ Encode® Converter). The manufacturing is carried out at a Zfx™ Milling Center or in an authorized milling lab. Only a single abutment change is done within the complete workflow.

1. BellaTek® Encode® Gingiva former on an implant in Region 36

2. Intra oral scan of the situation on the Intra-oral scanner‘s screen

3. STL-Data of the created 3D model, based on the digital impression

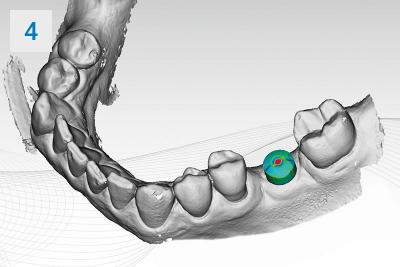

4. Automatic decoding of 3D information for the implant type - integrated on the gingiva former defining the implant diameter and its‘ length such as for the shaping of the emergence profile

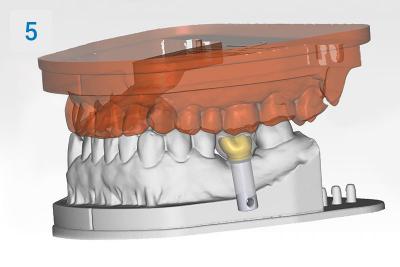

5. Computer-aided construction of the abutment

6. Physical model with integrated implant analog

7. Crown from zirconium dioxide and ZrO2 Abutment with titanium base manufactured at the Zfx™ Milling Centre

8. Abutment on the model

9. Crown on the model

10. Abutment with integration support from light-curing plastic on model

11. Abutment on situ

12. Crown in patient’s mouth, direct after integration

© 2024 |

Zfx GmbH - A company of ZimVie